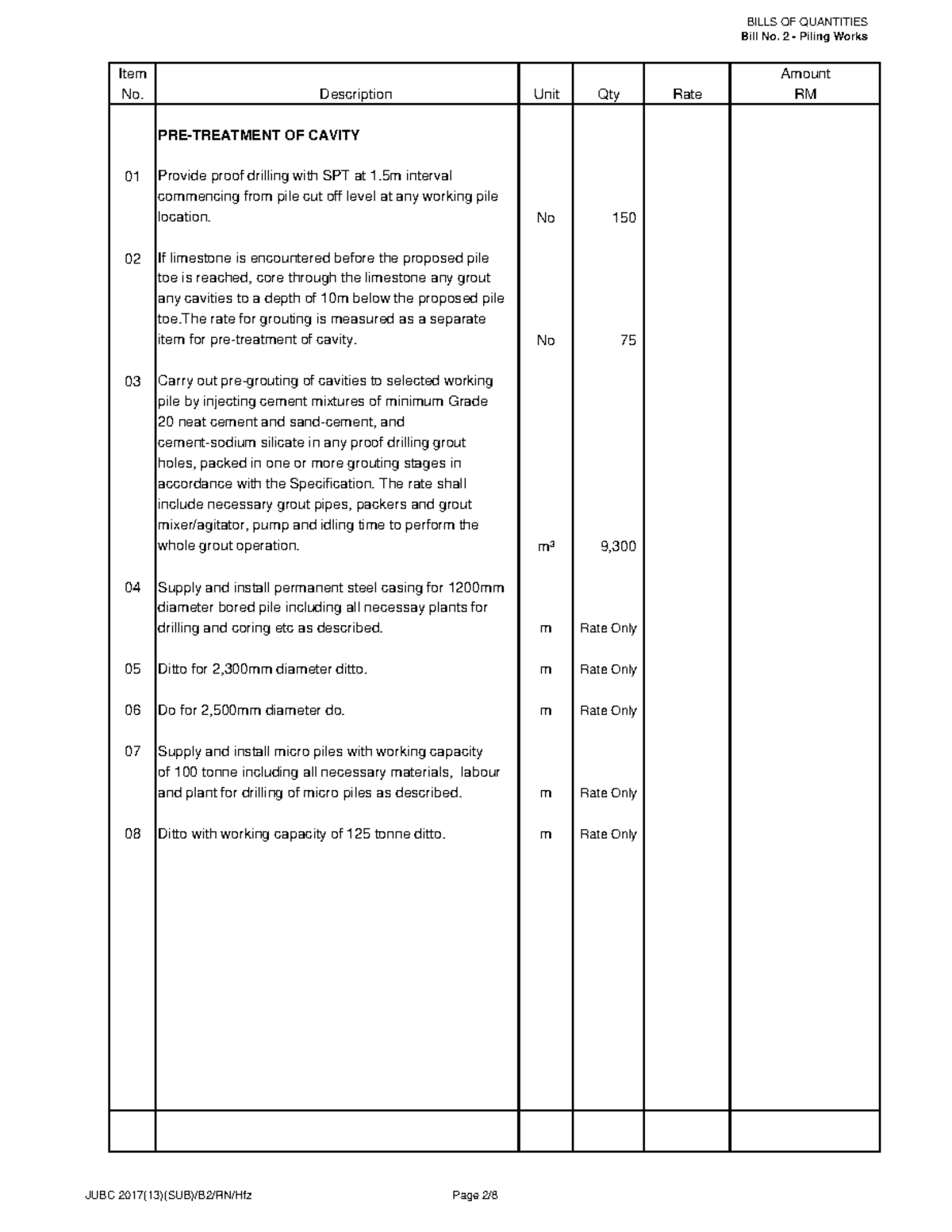

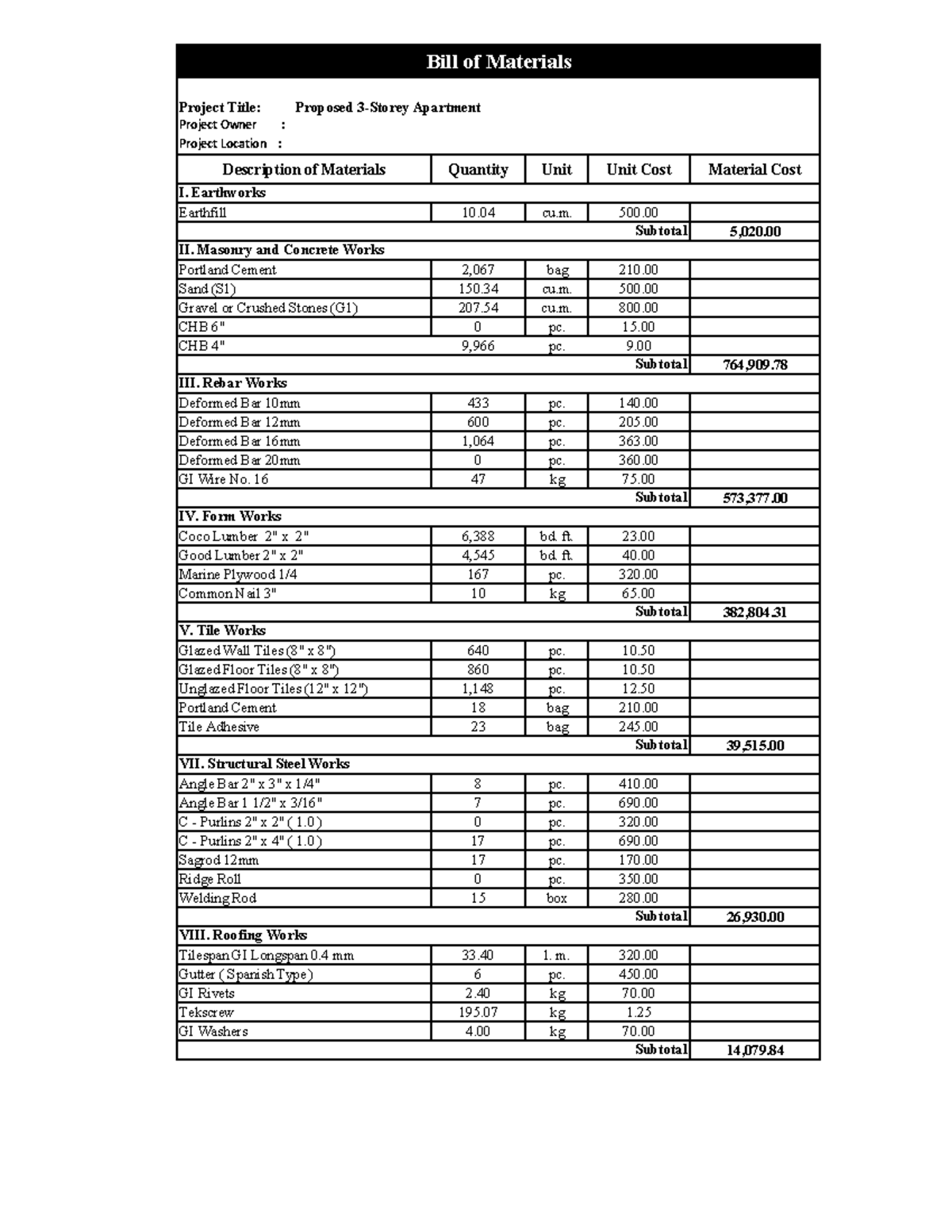

It typically incorporates sales order details corresponding to uncooked supplies, manufacturing orders, part names, pricing, and labeling, to call a few. This is the high-level BOM that lists the materials required to manufacture or assemble the product. If there have been subassemblies, mixes, blends, or different components required to produce these materials, they aren’t listed and the completed element for the ultimate manufacture is all that’s shown.

- Modular BOMs record the supplies, documents, elements, and engineering drawings and diagrams you have to complete a subassembly.

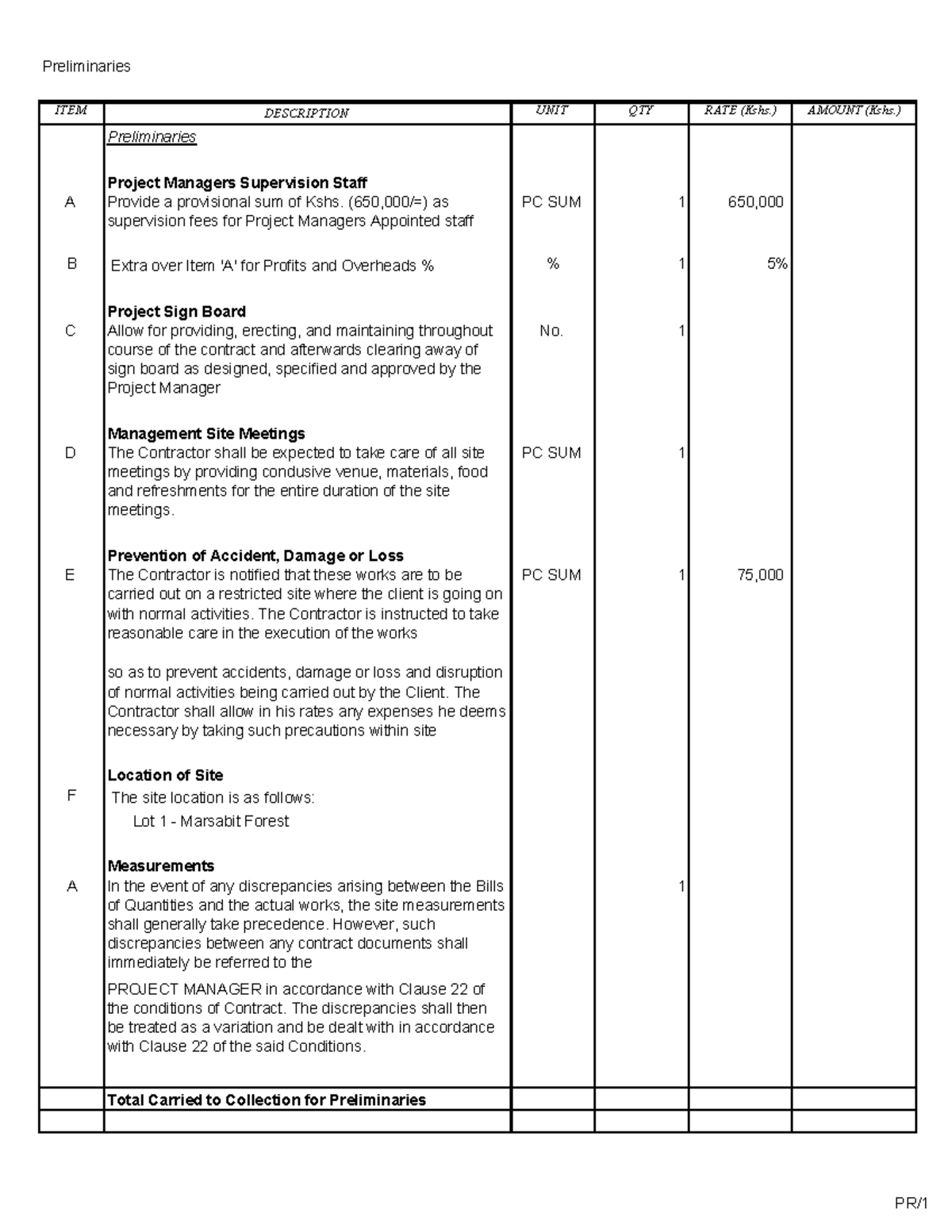

- If you’re organizing a posh or cross-functional project, you could want multiple kinds of BOMs.

- Bill of Materials are complicated and often reflect the complexity of the product growth process and the complexity of the product itself.

- Moreover, the BOM is important for high quality management, because it outlines the specs of each element, making certain that only appropriate supplies are utilized in production.

- A software program system specialised in BOM administration is extra scalable and dependable.

So, is the BOM for completed merchandise, raw supplies, or operations costs like machine maintenance? The Single-Level BOM offers a simplistic view of a product’s construction. It lists only the primary components required to build the product with out diving into sub-assembly particulars.

Multi-level (or Indented Bom)

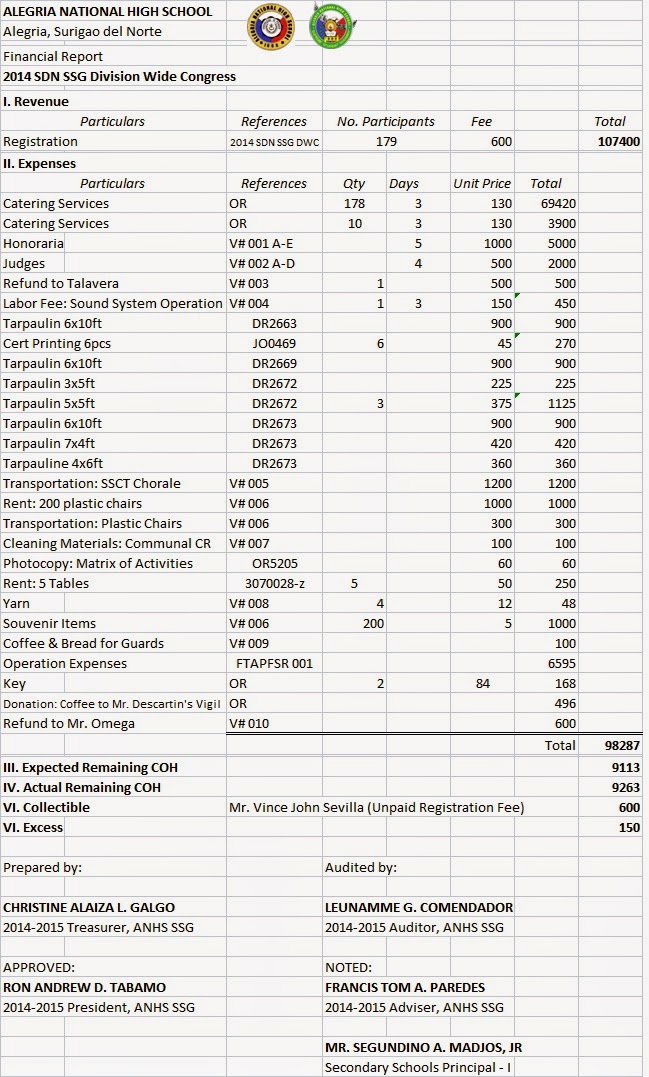

This allows for accurate calculation of the value of goods bought (COGS), which is essential for pricing choices and profitability analysis. Furthermore, the BOM is crucial for stock administration, because it allows correct forecasting of material wants and environment friendly management of inventory ranges. The BOM plays a vital role in varied elements of product management and operations. It is the foundation for materials necessities planning (MRP), enabling correct forecasting of fabric needs, environment friendly procurement, and cost-effective inventory management. The BOM additionally guides the production process, guaranteeing that all needed parts are available when needed, and that they are assembled in the right sequence. BOM explosion involves dissecting a high-level BOM into its minutest components and supplies.

A manufacturing BOM is required earlier than designing enterprise useful resource planning (ERP) methods and in materials requirement planning (MRP). Modular BOMs listing the materials, paperwork, elements, and engineering drawings and diagrams you should full a subassembly. Use modular BOMs when your deliverables have a quantity of possible combos of modules, similar to an promoting marketing campaign with varied advertisements showcasing the totally different advantages of your product or service. However, as a outcome of it doesn’t show the interconnectedness between parts and subassemblies, the single-level BOM’s simplicity can be a downside for complex merchandise.

An example of an Engineering BOM could be an organization that produces a new scooter using 3D printed components or a revolutionary technology for propulsion. It would comprise an in depth list of all elements required to deliver the model new product to market. The EBOM can also be used by planners, buying, and finance to trigger purchases for supplies from present distributors or to supply distributors for model new supplies.

Ignoring Bom Audits And Reviews

It includes all the components and assemblies required to create the product prototype. The MBOM, then again, is a detailed guide for manufacturing the product. It contains all of the materials, components, and assemblies required for production, along with their portions and assembly sequence. It lists all of the replaceable elements and components of a product, aiding in repair and maintenance duties. Understanding the BOM is essential for anybody concerned in product administration, operations, manufacturing, and provide chain administration. It is a pivotal device that ensures the graceful execution of manufacturing processes, facilitates environment friendly useful resource planning, and aids in cost estimation.

Structure

Invoice of materials (BOMs) are essentially project “recipe” cards—gather your components, follow the steps to a tee, and you’ve got https://www.simple-accounting.org/ a deliciously profitable end outcome. Simply like your favourite cookie recipe, use a BOM to help organize and lay out the necessities needed to complete a project. Many manufacturing firms produce the same product in quite so much of sizes, colours, or different parameters. Some producers additionally produce the identical items for various brands beneath a “white label” arrangement. This signifies that the core product and bulk of producing will be the similar, but the final model might differ barely depending on the client.

We’ll even embrace a free bill of materials template to facilitate the method. The CBOM is used to dynamically create “end-items” that an organization sells. The advantage of using CBOM construction is that it reduces the work-effort needed to take care of product buildings. The development of the CBOM is dependent on having a modular BOM structure in place.

This might mean totally different packaging, volume, unit rely, branding or stamping, and different variations to make the product relevant to the customer’s use or brand. A configurable BOM (also called a Matrix BOM, a BOM with parameters, or just a product configurator) is a type of producing BOM used to manage the manufacturing of configurable merchandise. To write a BOM, you have to embody the name of each element, part quantity, part description, supply, quantity per meeting, unit of measure for quality and any notes. Managing BOMs also requires an organization to contemplate how and the place they retailer their invoice of materials documentation.

It is essential to have a BOM precisely made to make sure no future points come up because of errors. If this list is inaccurate, it will put the manufacturing course of on hold, thereby disturbing the complete manufacturing, distribution, and sale schedule. In addition, it might involve high operating prices in controlling the damage done. This shows how essential bill of materials management and preparation are. Thirdly, the BOM ought to be frequently updated to reflect adjustments in the product design or the introduction of recent supplies or components.